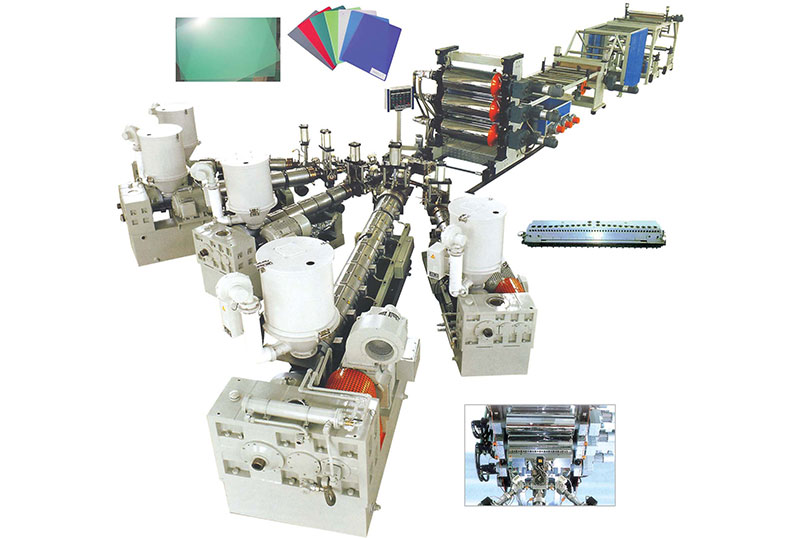

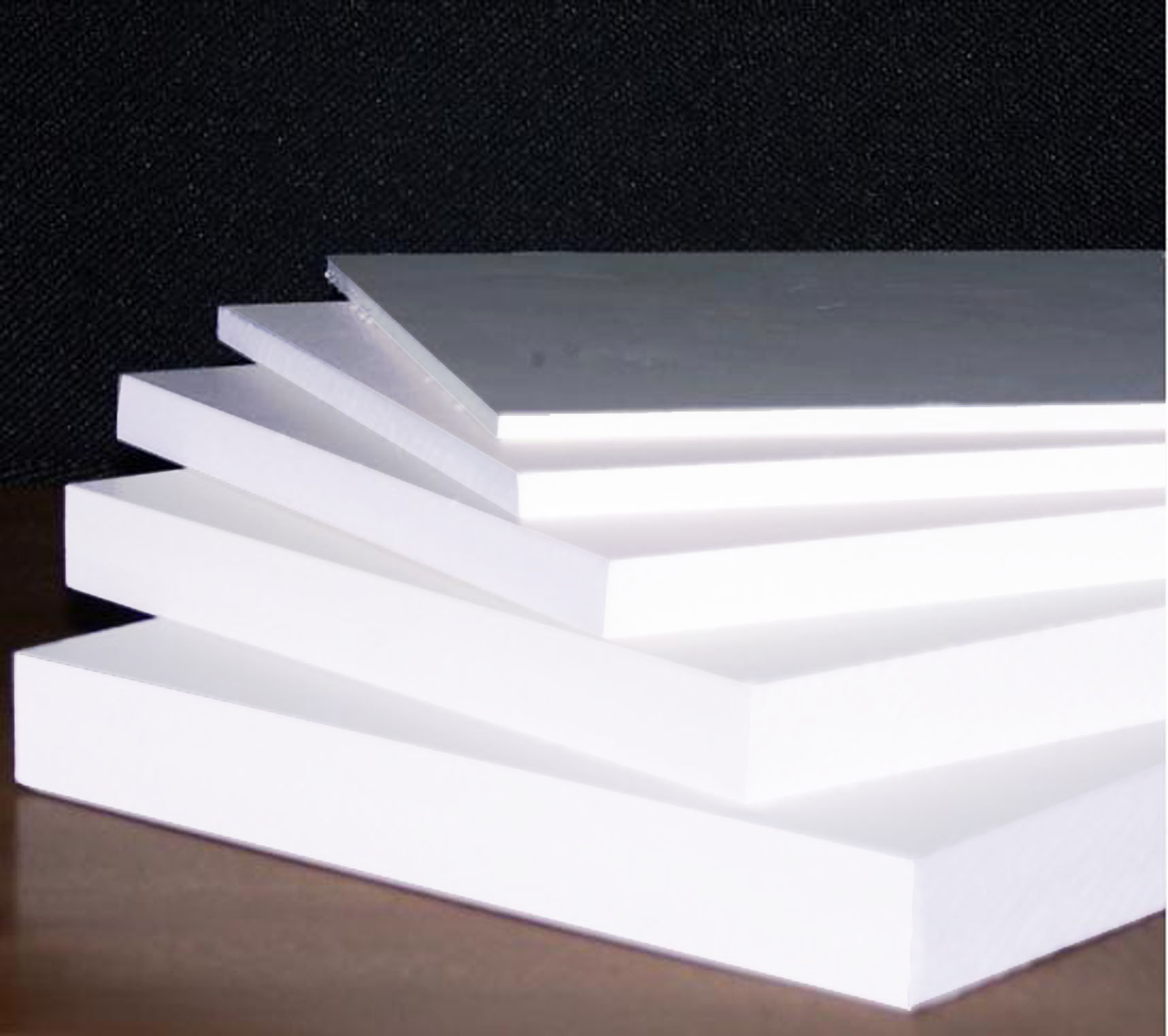

WPC PVC Crust Foam Board Extrusion Line

Detail Technical Parameters

(Mufananidzochete kune referensi)

General tsananguro

1, Saizi yechigadzirwa: hupamhi 1250mm / ukobvu: 2-30mm (Kubva pane zvinodiwa nemutengi)

2、Main Material: WPC Inosanganisa, kugadzirisa zvinowedzera uye mumiriri wekuzadza

3, Extruder: SJSZ80/156 conical double screw extruder

4, Output: kumativi 7ton/zuva

5, Tembiricha yemvura inotonhorera: <15 ℃ Mhepo yekumanikidza:> 0.6Mpa

6, Simba rekupa: 3Phase / 380V/50HZ (Kubva pane zvinodiwa nemutengi)

B.Detail Technical Parameters yeChimwe chimwe chikamu

1. Screw Automatic loader

| Item | Tsanangudzo | Unit | mashoko |

| |||

| 1 | Rated Charge Capacity | Kg/h | 450 |

| 2 | Max kuchaja huwandu | Kg/h | 450 |

| 3 | Motor Power | KW | 1.5 |

| 4 | Hopper volume | Kg | 120 |

| 5 | Spring dhayamita | mm | 36 |

| 6 | Kuchengeta vhoriyamu | kg | 150 |

2. SJSZ80/156 Conical Double Screw Extruder

| ﹡Screw, dhizaini dhizaini uye kugadzira kunotora European advanced tekinoroji ﹡Screw uye mbiya zvinhu: 38CrMoAlA, Nitriding kurapwa ﹡adopt yepakutanga yakakurumbira zvinhu zvemagetsi zvine yakakwirira yakatsiga kumhanya mhando.Eg: RKC kana Omron tembiricha controller, ABB yekumhanyisa regulator, yakaderera-voltage breaker inotora Schneider kana Siemens ﹡Gearbox tora yakakwirira torque, yakaderera ruzha, yakaoma giya zino kumeso giya bhokisi ﹡Kuzvidzivirira system: yazvino yemotor overload otomatiki kumira kudzivirira screw displacement automatic stop protection Mafuta ekuzora nzara otomatiki aramu mudziyo | |||

| 1 | Screw Diameter | mm | ¢80/156 |

| 2 | Screw Length | mm | 1800 |

| 3 | Screw kutenderera kumhanya | r/min | 0-37 |

| 4 | Material of Screw uye Barrel | / | 38CrMoAlA Nitrogen Kurapa |

| 5 | Kudzika kwenitrate kesi | mm | 0.4-0.7mm |

| 6 | Kuoma kwe nitration | HV | 》950 |

| 7 | Kushata kwepamusoro | Ra | 0.4un |

| 8 | Kuoma kwemaviri alloys | HRC | 55-62 |

| 9 | Kudzika kwemaviri alloys | mm | 》2 |

| 10 | Kupisa Simba | KW | 36 |

| 11 | Barrel Heating | / | Kukanda Aluminium Heater |

| 12 | Screw core tembiricha control | / | Automatic kutenderera tembiricha kutonga |

| 13 | Kupisa nzvimbo | / | 4 |

| 14 | Kutonhora | / | blower kutonhora |

| 15 | Screw core tembiricha kugadzirisa | / | Nedenderedzwa conduction mafuta |

| 16 | Screw quantity | 2pcs | |

| Muchina furemu | Welding yesimbi pombi uye iron plate | ||

| Gear box | |||

| 1 | Inoshanda mwero | / | JB/T9050.1-1999 |

| 2 | Material yegiya uye shaft | / | Gamuchira yakakwira simba alloy, carburizing uye kudzima, kukuya |

| 3 | Gear nemazvo uye kuoma | / | 6grade, HRC 54-62 |

| 4 | Kuvhara mafuta | Kuiswa chisimbiso kwese kunotora zvigadzirwa zvakanaka | |

| 5 | Screw Safeguard | / | Automatic screw displacement alarm |

| 6 | Brand | DUOLING (JIANGYIN) | |

| 7 | gear bearing | NSK | |

| 8 | giya rinotakura MATERIAL | 20CrMnTi Nitriding mazino akaomarara pamusoro | |

| Dosing yekudyisa mudziyo | |||

| 1 | Kudyisa speed regulator | / | ABB frequency kutendeuka |

| 2 | Inogona kugadziriswa zvakasiyana kana kuwiriraniswa kugadzirisa ne extrusion. | ||

| 3 | Kudyisa mota 1.5kwMaterial Stainless simbi | ||

| Mota nemagetsi system | |||

| 1 | Motor Power | KW | 75 (AC mota) |

| 2 | Speed kugadzirisa mode | / | Variable frequency conversion |

| 3 | Output Capacity | Kg/h | 400 |

| 4 | Temperature Controller | / | RKC, Japan |

| 5 | Frequency inverter | / | ABB |

| 6 | AC contactor | / | Siemens |

| 7 | Voltage | / | Maererano nezvinodiwa |

| 8 | Motokari brand | Siemens | |

| 9 | Extruder axis urefu | mm | 1000 |

| 10 | |||

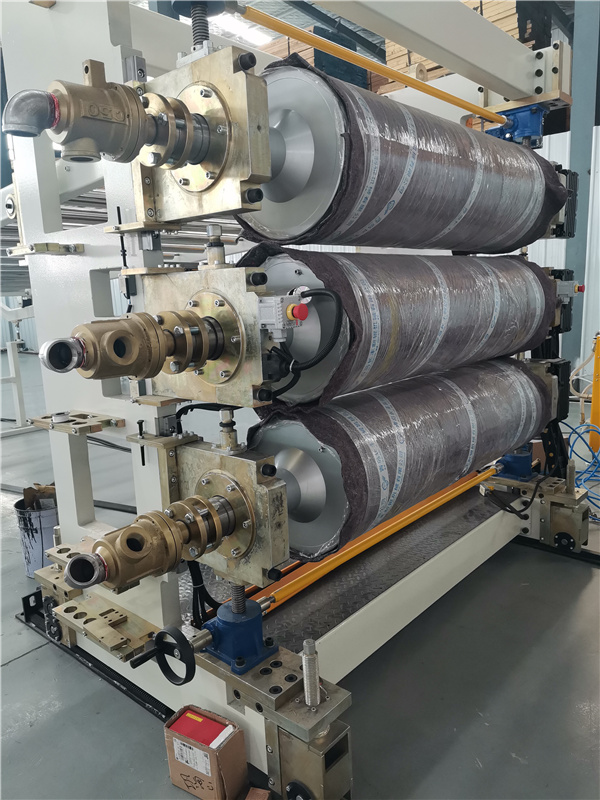

3. Die musoro uye calibrating Molds (kusanganisira mold tembiricha controller)

| Item | Tsanangudzo | |

| Kugadzirisa mudziyo une choke plug: 1 seti yemuromo unofa.Muromo wepamusoro unofa unogona kugadziriswa uye muromo wepasi unofa unogona kutsiviwa.Yakashongedzerwa nedhivha ine inogadziriswa die lifting.Iyo mold lip yakashongedzerwa neinotenderera kupisa mafuta ekufambisa mudziyo, ine mold tembiricha muchina. Kubudirira kwehupamhi hwemusoro wekufa: 1350mm Channel mode: zvipfeko hanger chiteshi inogamuchirwa Product upamhi: 1220mm Ukobvu hwezvigadzirwa zvefoam board: 3-25mm Chikamu chekudziya: Zone 7 Iyo difa inogadzirwa neyemhando yepamusoro alloy simbi uye die simbi forgings, uye pamusoro pemumhanyi wemukati ndeye chrome yakaputirwa uye yakakwenenzverwa. Mold chimiro: chimiro che mold chinotora tekinoroji inotengeswa kunze kwenyika, uye mukati megomba remukati rakaputirwa nehard chromium uye rakakwenenzverwa kugirazi rakajeka. Kugadziriswa kwehukobvu: mabhaudhi anogadziriswa akaiswa pamuromo wekufa, anogona kugadziridzwa kana uchigadzira mahwendefa ane ukobvu hwakasiyana. Heating fomu: Stainless simbi yemagetsi kupisa tsvimbo inoshandiswa kupisa, ine yunifomu inobuda uye kugadzikana kwakanaka. Mold trolley, bracket type, ine vhiri rekufamba. Material: square chubhu simbi ndiro welding yakasimbiswa chimiro Kugadzirisa nzira: screw kugadzirisa Kugadzirisa kureba: 100mm | ||

PVC foam board muchina Spare parts: Zvishandiso runyorwa:

| NO | Spare parts name | Quantity |

| 1 | Kanda alumium hita ye1 zone | 1 pcs |

| 2 | Kutonhodza mhepo feni yedhiramu | 1 pcs |

| 3 | Spanner ye mold | 1 pcs |

| 4 | contactors | 2 pcs |

| 5 | Thermocouples | 5 pcs |

| 6 | kupisa tsvimbo kune abrasives | 5 pcs |

| 7 | copper feeler gauge | 1pcs |

| 8 | kufa kugadzirisa mabhaudhi | 5 pcs |

| 9 | Kudyisa chitubu chemuchina wekudyisa | 2 pcs |

| 10 | Pe pipe yemuchina wekudyisa | 2 pcs |

| 11 | mhepo pombi connectors | 5 pcs |